Tearing Resistance Testing fabrication|tear resistance testing machine : manufacturers Find out more about the techniques and methods given in these standards for the determination of tearing resistance curves (R-curves) in single-edge notched bend (SENB) fracture . Rua Antonio Camardo, 856 - Tatuape, Sao Paulo - SP. Agendar online agora. Ver telefone.

{plog:ftitle_list}

Spin the Wheel é um girador de roda para ajudar a decidir ao fazer uma escolha aleatória. Se você precisa de uma roda da sorte, uma aleatória gerador de números, uma roda de nomes, uma gerador de sorteio, uma roda da fortuna para jogos ou um simples sim ou não, basta girar a roda para obter o que você precisa.

ASTM D1922: This standard measures the propagation tear resistance of plastic films and thin sheeting. ASTM D689: This standard applies to measuring tearing resistance of paper. ISO 1974: This standard details the tearing resistance test for paper and board using the internal tear .

How the Tearing Resistance Tester Works. The process of testing tear resistance involves creating a slit in the material sample, which is then subjected to a tearing force. The tester .Tear resistance testing can be found in plastic film, paper and textile industries. Tear resistance is the measurement of a sample's ability to resist tearing. Tear resistance can be impacted considerably by the speed of the test, e.g. test .

Tear testing is a mechanical testing procedure used to measure a material’s resistance to tearing. It involves applying a controlled force to a specimen, often with a pre-initiated tear or cut, to evaluate how the material behaves under .

Find out more about the techniques and methods given in these standards for the determination of tearing resistance curves (R-curves) in single-edge notched bend (SENB) fracture .The main cause of lamellar tearing is very high out-of-plane stresses due to restraint of weld shrinkage. Tearing will usually appear during or soon after cooling of the welds; tearing due to .ASTM D1938 – Standard Test Method for Tear-Propagation Resistance (Trouser Tear) of Plastic Film and Thin Sheeting by a Single-Tear Method; ASTM D2261 – Standard Test Method for .

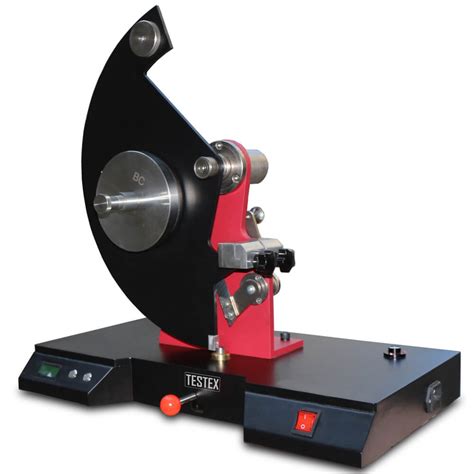

A tearing resistance curve, or R-curve, represents a material's resistance to progressive crack extension (this implies that a material's fracture toughness can change with crack extension).Tear resistance can be gauged via the same ASTM D 412 apparatus used to measure tensile strength, modulus and elongation. ASTM D 624 can be applied to measure the resistance to .The Elmendorf test, named after its inventor Armin Elmendorf, is a widely recognized method for assessing tear resistance, providing valuable insights into a material’s ability to withstand .

ISO 1974:2012 specifies a method for determining the (out-of-plane) tearing resistance of paper. It can also be used for boards having a low grammage if the tearing resistance is within the range of the instrument. ISO 1974:2012 does not apply to corrugated fibreboard, but it may be applied to the components of such boards. When it comes to textiles, tear strength is a crucial factor in determining the durability and quality of fabric. It refers to the resistance of a fabric to tearing under stress or force. Properly measuring tear strength is . A video clip from Corus showing what non-destructive testing (NDT) is and the methods commonly used in non-destructive testing of welded steel components to ensure there is no unacceptable defects which can affect the mechanical properties of metallic component. Processes include magnetic particle testing and ultrasonic testing. The test results indicated the feasibility of SGP in enhancing the wear resistance of GCr15 bearing steel friction shims under heavy loads in terms of the application scenario of civil engineering. The SGP-treated sample had a more stable friction coefficient (0.475) and slighter wear compared to the other two samples due to its enhanced layer .

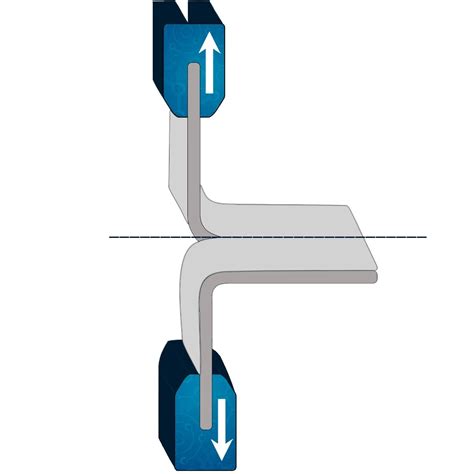

Tear strength is measured in newtons per mm or pound-force per inch (N/mm or lbf/inch). Testing Tear Strength: A How-To Guide. Testing tear strength is generally performed in a tensile test rig. A sample is clamped to the upper and lower jaws of the test machine. It is oriented such that the stress is applied as a tearing motion.There are three main standards which describe the fracture toughness testing of ductile alloys by generating tearing resistance curves: BS 7448-4 (1997), ISO 12135 (2016) and ASTM E1820 (2018). Each of these standards differs in significant details relating to the generation and analysis of the test data.

what is tear strength tester

Widening the welding lobe of advanced high strength steels in the resistance spot welding process. . Lamellar tearing in welded steel fabrication by J C M Farrar and R E Dolby Please note This PDF file has been made by scanning an original booklet. . Product type. Negotiation with steel suppiiers. Ultrasonic testing of plate. Destructive .The tensile strength of a material is the maximum mechanical tension it can withstand before it cracks. It is given in N/mm² or MPa. The tear resistance of a material, also called tensile strength at break, is the mechanical tensile stress at the exact moment of tearing and is also given in N/mm² or MPa.. Since the maximum tensile stress and the tensile stress at the moment of .There are three main standards which describe the fracture toughness testing of ductile alloys by generating tearing resistance curves: BS 7448-4 (1997), ISO 12135 (2016) and ASTM E1820 (2018). Each of these standards differs in significant details relating to the generation and analysis of the test data.area in a through thickness tensile test is a good general guide to the lamellar tear re-sistance, i.e. the risk of lamellar tearing decreases with increased reduction of area. Steel normally manufactured to the EN stand-ards (e.g. EN 10025-2) generally has a modest tear resistance (i.e. a modest reduction of

Digital Thickness Meter tv shopping

Purpose of a tear test: The overall goal of a tear test is to determine a materials ability to resist the growth of the initial tear or its “tear resistance”. The value of a material’s tear resistance is generally accepted to be the force required to complete the tear so that it has gone completely though the material so that it has been .ISO 1974 was prepared by Technical Committee ISO/TC 6,Paper, board and pulps, Subcommittee SC 2, Test methods and quality specifications for paper and board. . This International Standard specifies a method for determining the (out-of-plane) tearing resistance of paper. It can also be used for boards having a low grammage if the tearing .

In this study, weldability and cracking susceptibility of SN 490C steel were firstly investigated. For this study, SN 490C thick plates which had been developed for anti-seismic steel of building structures were welded by flux-cored arc welding (FCAW) and submerged arc welding (SAW) processes based on welding conditions of actual construction site. Weldments using .

Digital Plastic and Rubber Thickness Meter tv shopping

tear testing methods

Tear resistance testing can be found in plastic film, paper and textile industries. Tear resistance is the measurement of a sample’s ability to resist tearing. Tear resistance can be impacted considerably by the speed of the test, e.g. test speed used in generate the tear. Tear propagation resistance for the purpose of acceptance testing is . The PCB fabrication process involves a range of quality control measures and testing to ensure a design can be produced reliably at scale. Many of these quality checks happen without the designer's direct .ISO 6383-1:2015(E) 8 Number of test specimens 8.1 A minimum of five test specimens shall be tested in each of the required directions of testing. 8.2 Specimens which show a tear out of line to the extent that the tear reaches one of the edges of the test specimen shall be discarded and further specimens tested (see 11.3). 9 Speed of testing

However, without improvement of short transverse ductility, certain dynamic service loads could cause lamellar tearing failures. Two alternate design paths are recommended to prevent tearing during fabrication or service loading. The current and proposed ASME requirements dealing with lamellar tearing are reviewed and recommendations are made.

The tearing strength tester is an appropriate tool to measure the tear resistance of various materials including textiles and fabric. Types of tear test: Tongue Test; Trapezoid; Elmendorf; Measurement of fabric tearing strength: Elmendorf tear tester: Sample Preparation: First we take specimen of 100 ×75 .Lamellar tearing occurs only in rolled steel products (primarily plates) and its main distinguishing feature is that the cracking has a terraced appearance. Lamellar Tearing. Cracking occurs in joints where: A thermal contraction strain occurs in the through-thickness direction of steel plate. A variety of materials are used in the Oil & Gas industry ranging from carbon steel, stainless steel to nickel alloys, etc. including non-metallic materials as well. Amongst these, carbon steel is the industry favorite because of many of its desirable attributes like machinability, weldability, availability, and cost. Wide use of carbon steel in the industry is also due to the .

Fabric tear resistance is crucial for safety, product durability, and customer satisfaction. The Elmendorf test is a standardized method widely used across industries. It helps quantitatively .

Tear resistance testing can be found in plastic film, paper and textile industries. Tear resistance is the measurement of a sample’s ability to resist tearing. Tear resistance can be impacted considerably by the speed of the test, e.g. test speed used in generate the tear. Tear propagation resistance for the purpose of acceptance testing is . Certain fibers and weaving methods result in fabrics with inherent abrasion resistance. Let’s look at how testing can reveal how different fabrics can hold up best along with time. Skip to content +86 769 2329 4842 [email protected] search Search. Menu. Home; . tear strength loss, hole formation, or other surface change compared to the .

The mean force required to continue the tearing of an initial cut in a single sheet of paper is expressed as the internal tearing resistance. If the initial slit is made in the machine direction, the result is given as machine direction tearing resistance and similarly for the cross-machine direction (ISO 1974). Why measure tearing resistance?This Complete Guide of the Elmendorf Tear Testing explores tear resistance testing dimensions, application areas, standards, methodologies, troubleshooting, and the future landscape of tear analysis. Key takeaways and practical insights empower informed decisions in material science. Application of Elmendorf Tear Testing in IndustryTearing Strength Tester. Tearing strength testing can be found in plastic film, paper and textile industries. It is used to describe how well a material can withstand the effects of tearing. Elmendorf tear is a common method that is used to test tear resistance. Hardness test results: The butt-joint manufactured by FCAW with the 30 mm thick plate, (a) face; (b) root. The butt-joint manufactured by SAW with the 70 mm thick plate, (c) face; (d) root.

tear resistance testing machine

web12 de set. de 2023 · Depois de entender estes significados, vamos ao veredito: o correto é “meio-dia e meia “! Isso porque o “meia”, neste caso, é um numeral que refere-se à metade de uma hora – é como .

Tearing Resistance Testing fabrication|tear resistance testing machine